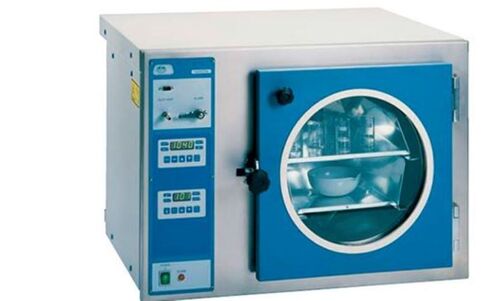

Microwave Digestion System

Microwave Digestion System Specification

- Features

- Fully programmable, safety interlocks, real-time monitoring

- Port Size

- Standard vessel lid ports

- Temperature

- Ambient to 300C

- Resolution

- 1C

- Interface Type

- USB, RS232

- Application

- Sample preparation, digestion of organic/inorganic samples

- Display Type

- Digital LCD touch screen

- Max Height

- Approx. 50 cm

- Humidity

- 80% (non-condensing)

- Test Range

- Up to 1000 mg sample per vessel

- Accuracy

- 2C temperature

- Number of Specimens

- 6-12 vessels per run

- Power Supply

- 230V AC, 50/60Hz

- Specimen Size

- Up to 1000 mg

- Gas Pressure

- Max. 40 bar (vessel pressure)

- Automation Grade

- Fully automatic

- Operating Voltage

- 220-240V AC

- Mounting Type

- Benchtop

- Response Time

- Immediate display

- Equipment Type

- Microwave Digestion System

- Measuring Range

- 0-300C (temperature), 0-40 bar (pressure)

- Frequency

- 2450 MHz

- Usage

- Laboratory sample digestion

- Capacity

- 6/12 vessel rotor

- Machine Weight

- Approx. 31 kg

- Test Speed

- Rapid digestion cycle (within minutes)

- Control Mode

- Microprocessor control

- Program Modes

- Custom, standard, and user-defined methods

- Material of Vessels

- High-purity TFM/PTFE

- Safety Features

- Pressure and temperature sensors, automatic shutoff

- Data Storage

- Internal memory for 100+ digestion programs

- Alarm System

- Audible/visual alerts on fault or completion

- Exhaust System

- Built-in exhaust and ventilation

- Door Design

- Enhanced safety locking mechanism

- Cooling System

- Integrated forced-air cooling

- Dimensions (WxDxH)

- 480 x 440 x 500 mm

- Color

- White or custom

- Microwave Power

- Up to 1000W adjustable

- Software Compatibility

- Windows-based PC software integration

Microwave Digestion System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 30 Days

- Main Domestic Market

- Karnataka, All India

About Microwave Digestion System

Our vision to excel and establish a strong foothold in the market has assisted us to evolve as a prominent supplier of Microwave Digestion System. It is used for performing digestion method for sensitive environmental and high organic content samples. The system completely breaks down samples such as pharmaceuticals, plants or food to make them ready for elemental analysis. Rotating carousel, and unique cavity design of this system ensures uniform microwave distribution. Microwave Digestion System is provided with pressure-responsive door and self-resealing mechanism for maximum safety.

Features:

- Automatic power control to match sample load

- Built-in temperature monitoring

- Corrosion-proof PTFE coated reinforced cavity

Reliable Safety and Control

This microwave digestion system includes multiple layers of safety, such as enhanced locking mechanisms, automatic shutoff, and real-time pressure and temperature tracking. The audible and visual alarm system immediately notifies users of faults or cycle completion, reducing operational risks and bolstering lab safety.

Efficient Sample Digestion Process

With rapid digestion cycles that complete within minutes, the systems high-purity vessels and powerful microwave energy ensure thorough and reproducible sample breakdown. The integrated cooling and exhaust systems maintain optimal working conditions, even in intensive protocols, maximizing efficiency during sample preparation.

User-Friendly Operation and Storage

Featuring a digital LCD touch screen and fully programmable microprocessor control, operators can set up custom, standard, and user-defined digestion programs. The robust internal memory stores over 100 workflows, while USB and RS232 options streamline data management. Windows-based software compatibility further enhances ease of operation.

FAQs of Microwave Digestion System:

Q: How does the microwave digestion system ensure user safety during operation?

A: The system utilizes advanced safety features, including pressure and temperature sensors, automatic shutoff, a secure door locking mechanism, and audible/visual alarms. Real-time monitoring and safety interlocks minimize risks, providing immediate alerts for faults or completion.Q: What materials are used for the digestion vessels, and why are they important?

A: The vessels are constructed from high-purity TFM/PTFE, which offer exceptional chemical resistance and purity, preventing contamination during digestion processes and ensuring reliable analytical results for both organic and inorganic samples.Q: When can rapid sample digestion be performed using this system?

A: Rapid sample digestion is possible any time, as the system features fully programmable modes with digestion cycles completing within minutes. This is ideal for laboratories requiring quick turnaround for routine or complex sample preparation.Q: Where can data from digestions be stored and managed?

A: Digestion programs and results are stored internally in the machines memory, which accommodates over 100 programs. Data management is enhanced by USB and RS232 interfaces, and integration with Windows-based PC software for seamless workflow.Q: What is the process for setting up and running a digestion program?

A: Users select or customize digestion methods via the LCD touch screen or compatible software. Parameters such as temperature, pressure, and power are set, samples are placed in high-purity vessels, and the system automatically manages digestion, monitoring, and safety until completion.Q: How does the integrated cooling and exhaust system benefit laboratory operations?

A: The forced-air cooling and built-in exhaust systems maintain stable internal conditions, prevent overheating, and efficiently remove gases, which safeguards sample integrity and operator safety throughout the digestion cycle.Q: What advantages does the microwave digestion system offer for laboratory sample preparation?

A: It delivers rapid, reproducible digestion of up to 12 samples per run, ensures high accuracy (2C), real-time monitoring, and easy automation. Safety, flexibility, and compatibility with Windows-based control software altogether enhance productivity and data integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Environmental Instruments Category

Nitron Automated Sample Digestion System

Price 990000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Laboratory chemical digestion

Features : Automated timer, fume extraction, preprogrammed protocols, safety alarms

Max Height : 48 cm

Temperature : Ambient to 450C

Analytical Vacuum Ovens

Price 250000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Sample drying and heating under reduced pressure

Features : Stainless steel chamber, high vacuum seal, builtin temperature protection

Max Height : 530 mm (outer dimensions)

Temperature : Ambient to 250C

Ultrapure Water System- Evo-RO Water Systems

Price 300000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Ultrapure Water Production

Features : Auto Cleaning, LCD Display, Water Quality Monitoring

Max Height : 800 mm

Temperature : 5C to 45C

HPLC Vial White /Amber

Price 1000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Laboratory, Analytical Chemistry

Features : Available in clear (white) and amber color for lightsensitive samples; high chemical stability; compatible with most autosamplers

Max Height : 32 mm

Temperature : 20C to +120C

Send Inquiry

Send Inquiry