Automated Workstation

Automated Workstation Specification

- Hardness

- Steel fixture (Rockwell HRC 55-60)

- Display Type

- 7-inch TFT LCD touchscreen

- Application

- Material testing, sample preparation, quality assurance

- Interface Type

- USB/RS232

- Power Supply

- AC 220V, 50/60Hz

- Mounting Type

- Benchtop

- Accuracy

- 0.5%

- Features

- Programmable tests, automatic data logging, emergency stop, secure locking tray

- Specimen Size

- Up to 22050 mm

- Frequency

- 50/60 Hz

- Test Range

- 0-5000N

- Gas Pressure

- 0.6 MPa max

- Port Size

- Standard USB/RS232

- Operating Voltage

- 220V AC

- Max Height

- 600 mm

- Automation Grade

- Fully automatic

- Number of Specimens

- Up to 10 at once

- Measuring Range

- 0.01N - 5000N

- Resolution

- 0.01N

- Humidity

- 20%-80% RH (non-condensing)

- Equipment Type

- Automated Workstation

- Temperature

- 10C - 40C

- Response Time

- 1 s

- Usage

- Laboratory, industrial inspection

- Capacity

- 5000N

- Machine Weight

- Approx. 95 kg

- Test Speed

- 10-1000 mm/min (adjustable)

- Test Width

- 250 mm

- Test Stroke

- 500 mm (max travel)

- Control Mode

- Automatic via touchscreen interface

- Noise Level

- <60 dB

- Material Construction

- Powder-coated steel, stainless fittings

- Sample Loading Method

- Motorized grips

- Data Storage

- Inbuilt memory up to 2000 test records

- Operating Environment

- Indoor, non-condensing

- Safety Devices

- Emergency stop, door interlock

- Calibration Method

- By certified calibration weights

- Software Compatibility

- Windows 10/11 supported data analysis

Automated Workstation Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 30 Days

- Main Domestic Market

- Karnataka, All India

About Automated Workstation

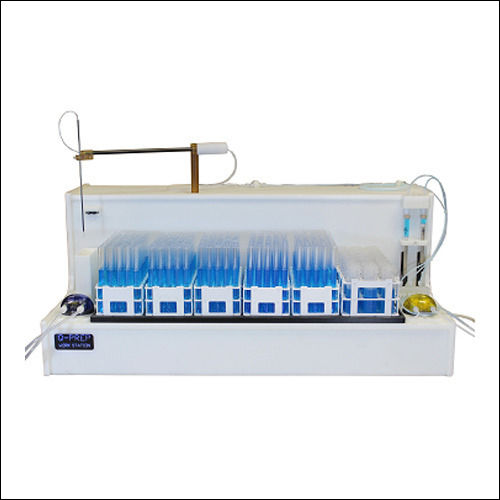

To establish a prominent presence in the market, we are engaged in supplying Automated Workstation. It is used in biology research labs and drug development labs to improve performance and productivity. This workstation is a perfect tool to minimize errors, reduce hands-on time, and increase throughput & reproducibility. Comes with a separate syringe pump assembly, it is used to manually dispense reagent. Automated Workstation can be used for sample preparation for genomics, proteomics, cellular analysis and more.

Features:

- Performs multiple dilutions

- Prepares auto sampler racks

- Spikes sample with internal standards

Precision and Efficiency in Material Testing

Engineered to streamline laboratory and industrial testing, this automated workstation offers exceptional accuracy (0.5%) across a broad 0.01N5000N measuring range. The motorized grips and programmable test modes provide versatile handling for varied specimen sizes (up to 22050 mm) and capacities. Its responsive touchscreen simplifies operation, enabling real-time adjustments and quick access to test data, supporting both rapid throughput and high data integrity for quality assurance applications.

Reliable Data Management and Connectivity

Storage of up to 2000 test records is integrated into the workstation, ensuring robust data retention and simplified workflow management. USB and RS232 interfaces, alongside native support for Windows 10/11, facilitate seamless data transfer and comprehensive analysis. Automatic data logging enhances traceability, supporting compliance and easy review of historical test results for regulatory or audit purposes.

Safety and Compliance Assured

Safety is built into every aspect, from the emergency stop and secure locking tray to the door interlock mechanism. Calibration is carried out with certified weights, guaranteeing measurement reliability. The workstation performs safely and quietly (under 60 dB), with environmental tolerance for 20%-80% relative humidity and 10C40C temperature, making it well-suited for various laboratory and industrial environments.

FAQs of Automated Workstation:

Q: How does the Automated Workstation ensure accurate and reliable test results?

A: The workstation employs certified calibration weights for measurement accuracy within 0.5%, with a resolution of 0.01N. Programmable test procedures and motorized grips provide consistent handling, while the 7-inch TFT LCD touchscreen interface allows precise control and real-time monitoring.Q: What types of materials and specimen sizes can be tested using this workstation?

A: It accommodates specimen sizes up to 22050 mm and supports a maximum testing force of 5000N. The workstation is ideal for various material testing applications in laboratories or industrial inspection settings, handling up to 10 samples at once for streamlined analyses.Q: When should I perform calibration, and what is the process?

A: Calibration should be performed at regular intervals or before critical testing sequences. The process involves using certified calibration weights as per the manufacturers instructions, ensuring measurements remain within the specified accuracy range.Q: Where is this workstation best suited for operation and installation?

A: Designed as a benchtop system, it is intended for use in indoor, non-condensing environments such as laboratories or industrial quality control departments, with optimal operation at 10C to 40C and humidity between 20% and 80% RH.Q: What are the main safety features incorporated in the workstation?

A: Safety is ensured through an emergency stop button, door interlock mechanism, and a secure locking specimen tray. These features protect both operators and specimens during all phases of automated testing.Q: How is data stored and accessed for analysis?

A: Data from up to 2000 test records is automatically logged in internal memory. Results can be accessed and exported via standard USB or RS232 ports for further analysis, with native compatibility for Windows 10/11 data processing applications.Q: What are the key benefits of using this automated workstation for material testing?

A: The system provides fully automatic, programmable testing to boost efficiency and accuracy, reduces operator intervention for safety, and offers comprehensive data management options. These advantages translate to increased throughput, streamlined documentation, and higher confidence in quality assurance outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Environmental Instruments Category

Air Sampling Pump

Price 38000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Personal and area air sampling

Control Mode : Manual and Automatic

Features : Portable, lightweight, rechargeable, flow control

Automation Grade : Semiautomatic

Gel Permeation Chromatography

Price 900000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Laboratory/Analytical

Control Mode : Microprocessorbased

Features : Auto sampler, Data acquisition software

Automation Grade : Semiautomatic

Ultra Pure Water System Evo-RO

Price 300000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Ultra Pure Water production by Reverse Osmosis

Control Mode : Microprocessor based automatic control

Features : Automatic flushing, Filter change alert, Digital monitoring

Automation Grade : Fully Automatic

Ultrapure Water System- Evo-RO Water Systems

Price 300000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Ultrapure Water Production

Control Mode : Automatic / Manual

Features : Auto Cleaning, LCD Display, Water Quality Monitoring

Automation Grade : SemiAutomatic

Send Inquiry

Send Inquiry