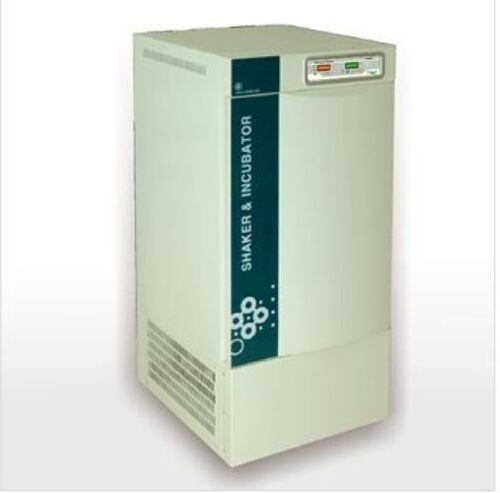

CO2 Incubator with Built-in Roller or Shaker

Price 400000 INR/ Piece

CO2 Incubator with Built-in Roller or Shaker Specification

- Number of Specimens

- 6 roller bottles or 8 shaker flasks

- Power Supply

- 220V AC, 50/60 Hz

- Specimen Size

- Roller bottle up to 1200 ml, shaker flask up to 500 ml

- Operating Voltage

- 220V/50 Hz

- Interface Type

- RS-232 data interface

- Max Height

- 950 mm

- Resolution

- 0.1C / 0.1%

- Automation Grade

- Semi-automatic

- Frequency

- 50/60 Hz

- Temperature

- Ambient +5C to 50C

- Gas Pressure

- 0.030.1 MPa (CO2)

- Measuring Range

- CO2: 020%

- Display Type

- Digital LCD

- Test Range

- Customizable roller/shaker speed

- Equipment Type

- CO2 Incubator with built-in roller or shaker

- Features

- Automatic UV sterilization, humidity tray, internal fan, data logging

- Port Size

- 28 mm CO2 gas inlet valve

- Application

- Cell culture, microbiology, tissue engineering

- Mounting Type

- Floor standing

- Response Time

- <60 sec (CO2 recovery to 5%)

- Accuracy

- 0.1C (temperature), 0.1% (CO2)

- Humidity

- 95% RH (3%)

- Usage

- Continuous CO2 incubation with agitation

- Capacity

- 170 L

- Machine Weight

- Approx. 95 kg

- Test Speed

- Variable (Rolling/Shaking: 560 rpm)

- Test Width

- 400 mm

- Test Stroke

- 200 mm (Shaker drive)

- Control Mode

- Microprocessor PID control

- Insulation Thickness

- 50 mm high-density thermal insulation

- Internal Material

- Stainless steel (304 grade chamber)

- Interior Light

- LED (optional)

- Alarms

- Temperature, CO2, power failure, door open

- Wheels/Casters

- Heavy-duty lockable casters

- Noise Level

- <50 dB

- Sterilization

- UV lamp cycle selectable

- Roller Drive

- Removable roller system for easy maintenance

- Shelf Number (Standard)

- 3 (adjustable)

- Window

- Heated anti-condensation glass

- Door Type

- Double door with inner glass viewing panel

- CO2 Sensor Type

- Infrared (NDIR)

About CO2 Incubator with Built-in Roller or Shaker

Roller Apparatus pr Shaker is mountable on the bottom of chamber. All operation for built-in apparatures is controlled at external control Panel.Sides Direct Heating System: Electric Heating wire is covered on all sides of chamber which makes stable uniformity and provides fast heat-up & temperature recovery. 3 parts of heating section are controlled and calibrated individually by 3 temperature sensors

Dry Wall and Air Jacket Warm Air from heating wire is preserved in space between chamber and insulation. It helps temperature recovered faster and minimize heat loss. Dry wall with insulation is not required to regular maintenance.

Precision Incubation and Agitation Combined

Experience seamless cell culturing with programmable roller or shaker actions, customizable between 5 and 60 rpm. The 170 L chamber, powered by microprocessor PID control and NDIR CO2 sensors, delivers consistent temperature and gas regulation essential for optimal growth. The adjustable roller drive and shaker accommodate various specimen sizes to suit diverse research needs.

User-Centric, High-Safety Design

A robust double-door system with an inner glass viewing panel allows safe visual monitoring without disrupting internal conditions. Audible and visual alarms promptly notify users of anomalies like high/low temperature, CO2 deviations, or power failures. Integrated automatic UV sterilization, high humidity, and an internal fan work together to minimize contamination and maintain environmental stability.

FAQ's of CO2 Incubator with Built-in Roller or Shaker:

Q: How does the CO2 incubator with built-in roller or shaker ensure precise environmental control for cell cultures?

A: The device uses a microprocessor PID control system and an advanced NDIR infrared CO2 sensor to maintain highly accurate temperature and carbon dioxide levels. Its 304-grade stainless steel interior, combined with 50 mm high-density thermal insulation and a heated anti-condensation glass window, helps to stabilize internal conditions, maintaining accuracy of 0.1C for temperature and 0.1% for CO2.Q: What is the process for sterilizing the chamber, and how often should it be performed?

A: The incubator is equipped with a selectable UV lamp cycle for automatic sterilization. UV sterilization can be scheduled as needed, usually between incubation runs or according to laboratory protocols, helping prevent microbial contamination without manual intervention.Q: When should I use the roller and when should I use the shaker feature?

A: The roller system is ideal for applications like cell culture in roller bottles, where gentle, continuous agitation encourages even cell growth. The shaker platform is better suited for flask-based cultures, such as those in microbiology or tissue engineering, which benefit from variable speed agitation (5-60 rpm).Q: Where is this equipment best suited for use?

A: This CO2 incubator is designed for research facilities, medical laboratories, biotech firms, and universities specializing in cell biology, tissue engineering, or microbiology. Its robust construction and versatile specimen handling make it suitable for demanding experimental protocols.Q: What benefits does the double door system with inner glass provide?

A: The double door system, featuring an inner glass viewing panel, reduces temperature and CO2 loss during specimen observation, minimizing disturbance to the internal environment. This helps maintain stable conditions, critical for sensitive culture work.Q: How is safety and sample integrity maintained during use?

A: Multiple alarm systems are active for temperature, CO2 gas, power failure, and door open status. The heated, anti-condensation glass, heavy-duty lockable casters, and automatic UV sterilization work together to protect cultures from contamination and ensure a secure working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Testing Instruments Category

High Performance Liquid Chromatography (HPLC) SYSTEM

Price 800000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Analytical separation and detection

Features : Autosampler, column oven, solvent tray, degasser, and leak sensor

Control Mode : Microprocessor/PCbased

Humidity : Below 80% RH, noncondensing

5 channel SPR with modular

Price 4500000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Laboratory / Industrial

Features : Modular design, simultaneous multichannel testing, programmable control

Control Mode : Touch panel / Programmable

Humidity : 20% ~ 80% RH (noncondensing)

Freeze Dryer Bench Top and Floor Types

Price 950000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Lab, Industrial

Features : Stainless Steel Chamber, Transparent Door, Portable Construction

Control Mode : Microprocessor based with LCD display

Humidity : 80% RH

Clarity Chromatography Software- calrity

Price 200000 INR / Set

Minimum Order Quantity : 01 Set

Usage : Chromatographic data management and instrument control

Features : Multiinstrument support, GLP/21 CFR Part 11 ready, data evaluation and reporting

Control Mode : Fully digital, automated control via software interface

Humidity : Operating 10% 80% noncondensing

Send Inquiry

Send Inquiry