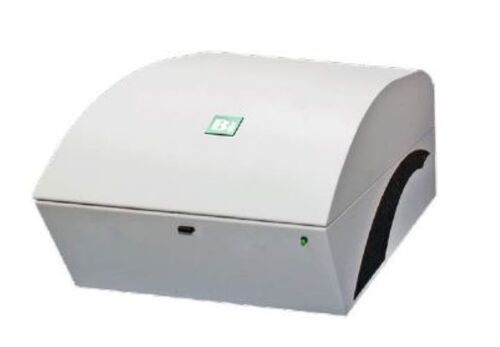

Express Microwave Ashing System

Price 1000000 INR/ Piece

Express Microwave Ashing System Specification

- Test Range

- Dynamic as per user-defined method

- Interface Type

- USB and RS232

- Humidity

- 2080% RH, non-condensing

- Specimen Size

- Up to 50 mL per crucible

- Temperature

- Ambient +5C to 1200C (programmable)

- Number of Specimens

- Up to 12 crucibles per batch

- Resolution

- 0.01% (ash content)

- Display Type

- Graphical LCD touch screen

- Automation Grade

- Fully automatic

- Power Supply

- 230 V AC, 50/60 Hz, single phase

- Features

- Auto shut-off, programmable methods, memory storage, safety interlocks, exhaust system

- Mounting Type

- Benchtop

- Port Size

- Standard exhaust port, 100 mm OD

- Frequency

- 2450 MHz

- Application

- Rapid ashing of organic/inorganic samples for analytical laboratories

- Accuracy

- 0.1% (ash content determination)

- Max Height

- 600 mm

- Response Time

- <20 seconds after program

- Gas Pressure

- 0.20.4 MPa (compressed air for exhaust)

- Operating Voltage

- 230 V AC

- Equipment Type

- Microwave Ashing System

- Measuring Range

- 0.01% to 100% ash content

- Usage

- Analytical sample preparation for ashing in laboratories

- Capacity

- 12 crucibles x 50 mL

- Machine Weight

- 80 kg

- Test Speed

- Programmable, up to 30 programs

- Test Width

- 250 mm

- Test Stroke

- Customizable, based on application

- Control Mode

- Microprocessor-based digital controller

- Heating Uniformity

- ±3°C throughout chamber

- Material Compatibility

- Organic/inorganic solid and liquid samples

- Ashing Mode

- Ramp and hold programmable, multi-stage

- Cooling Time

- <15 minutes down to room temperature

- Microwave Power Output

- Up to 2000 W adjustable

- Safety Protection

- Door interlock, over-temperature protection, exhaust fan

- Calibration

- User calibration mode with reference standards

- Chamber Material

- High purity quartz/ceramic

- Data Storage

- Up to 30 programs with history recall

- Sample Placement

- Removable crucible holder tray

- User Interface

- Multi-language touch screen menu

- Exhaust System

- Built-in active exhaust & filtration system

- Internal Chamber Size

- 350 mm x 350 mm x 300 mm

- Software Upgradability

- Via USB port

About Express Microwave Ashing System

QAsh achieves fast ashing times by combining in-situ airflow with a microwave. It has a large floor area to accommodate a large number of samples and is suitable for polymers, oils, food, pulp, sludge, and many other sample types.Superior Microwave Ashing Performance

Experience unmatched heating uniformity and speed with the Express Microwave Ashing System, enabling precise determination of ash content for various sample types. The programmable power output and dynamic temperature range ensure optimal processing for both organic and inorganic substances across multiple laboratory applications.

Advanced Safety and Control Features

Safety is paramount with integrated door interlocks, over-temperature protection, exhaust fan, and a built-in filtration system. The microprocessor-based digital controller and touch screen interface allow for easy programming, multi-language accessibility, and effortless software upgrades via USB.

Efficient Sample Processing and Data Management

Process up to 12 specimens simultaneously using removable crucible trays and store up to 30 program histories for reliable tracking. Fast cooling, customizable testing parameters, and secure program memory offer high throughput and reproducibility, ideal for modern laboratories requiring efficient ashing solutions.

FAQ's of Express Microwave Ashing System:

Q: How does the Express Microwave Ashing System ensure precise ashing of laboratory samples?

A: The system utilizes adjustable microwave power output up to 2000 W, high purity quartz/ceramic chambers, and programmable multi-stage ramp and hold ashing modes to deliver exceptional heating uniformity and accuracy for both organic and inorganic samples.Q: What safety mechanisms are incorporated in the Express Microwave Ashing System?

A: Safety features include a door interlock, over-temperature protection, exhaust fan, and a built-in active exhaust and filtration system, ensuring secure operation and protection for laboratory personnel.Q: When is it beneficial to use microwave ashing over traditional methods?

A: Microwave ashing significantly reduces processing time and provides fast cooling (<15 minutes), greater efficiency, enhanced accuracy (0.1%), and programmable automation compared to conventional furnace ashing, making it ideal for high-throughput analytical laboratories.Q: Where is the Express Microwave Ashing System commonly used?

A: This equipment is widely utilized in analytical laboratories for rapid ashing and determination of ash content in solid and liquid samples, supporting sample preparation in quality control, research, and industrial analysis.Q: What is the process for sample placement and ashing with this system?

A: Samples are placed in removable crucible holder trays, with up to 12 specimens per batch. The ashing process is programmable via the graphical LCD touch screen, allowing custom methods and multi-stage ramp and hold settings tailored to specific sample requirements.Q: How does the built-in exhaust and filtration benefit laboratory workflow?

A: The active exhaust and filtration system effectively removes fumes and particulates during ashing, ensuring a cleaner laboratory environment and reducing the risk of contamination or exposure to hazardous materials.Q: What advantages does the system offer in terms of data management and software upgradability?

A: Users can store up to 30 programs with history recall, access multi-language menus, and update software easily via the USB port, promoting efficient operation and future-proofing laboratory workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Testing Instruments Category

Freeze Dryer Bench Top and Floor Types

Price 950000 INR / Piece

Minimum Order Quantity : 01 Piece

Control Mode : Microprocessor based with LCD display

Equipment Type : Freeze Dryer Bench Top & Floor Model

Response Time : 2 min

Operating Voltage : Single/Three Phase

Benchtop SPR with analysis module

Price 4500000 INR / Piece

Minimum Order Quantity : 01 Piece

Control Mode : Computer controlled (via analysis module)

Equipment Type : Benchtop Surface Plasmon Resonance (SPR) Analyzer

Response Time : <2 seconds

Operating Voltage : 100240 V AC

Automatic Melting Point Apparatus

Price 350000 INR / Piece

Minimum Order Quantity : 01 Piece

Control Mode : Microprocessor based automatic control

Equipment Type : Automatic Melting Point Apparatus

Response Time : < 2 seconds for temperature change

Operating Voltage : 220240V AC 10%, 50Hz

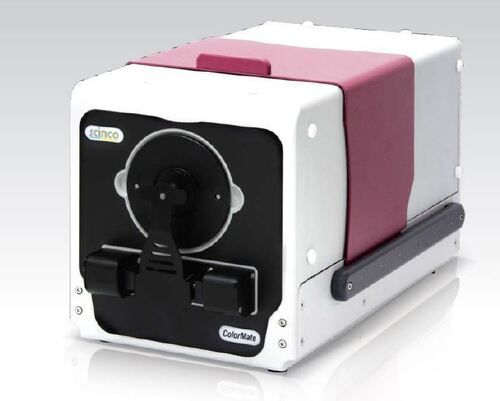

Colour Specrophotometer

Price 900000 INR / Piece

Minimum Order Quantity : 01 Piece

Control Mode : Manual/Automatic

Equipment Type : Colour Spectrophotometer

Response Time : 1.5 seconds

Operating Voltage : DC 5V

Send Inquiry

Send Inquiry