Latest Technology Ultrapure Water System

Price 300000 INR/ Piece

Latest Technology Ultrapure Water System Specification

- Port Size

- 1/4 inch inlet

- Measuring Range

- 0.05518.2 Mcm

- Test Range

- Up to 18.2 Mcm resistivity

- Accuracy

- 2%

- Mounting Type

- Benchtop

- Application

- Laboratory, Research, Pharmaceutical, Electronics

- Frequency

- 50/60 Hz

- Interface Type

- RS232

- Max Height

- 900 mm

- Resolution

- 0.01 Mcm

- Operating Voltage

- 220V AC

- Features

- Touch screen, automatic maintenance alerts, integrated pretreatment and polishing

- Response Time

- Instant (<10s)

- Hardness

- Adjustable via pretreatment stage

- Automation Grade

- Fully Automatic

- Humidity

- 1090% RH (non-condensing)

- Display Type

- Digital LCD

- Equipment Type

- Ultrapure Water System

- Temperature

- 5C 40C

- Power Supply

- 220V AC, 50Hz

- Usage

- Ultrapure water production

- Capacity

- Up to 15 liters/hr

- Machine Weight

- Approx. 80 kg

- Control Mode

- Microprocessor based automatic control

- TOC Level

- < 5 ppb (Total Organic Carbon)

- Conductivity Sensor

- High precision dual-range

- Storage Tank

- Integrated, with sterile vent filter

- Compliance

- Meets ASTM Type I water standards

- Recirculation System

- Built-in continuous recirculation

- Material of Construction

- High-grade stainless steel and medical-grade plastic

- Water Purification Stages

- Multi-stage including reverse osmosis, UV, and ultrafiltration

- Endotoxin Level

- < 0.001 EU/ml

- Dispensing Options

- Volume-controlled and manual

- Filter Lifespan Indicator

- Yes, with digital alert

- Noise Level

- <50 dB

About Latest Technology Ultrapure Water System

They produce Type I grade water of which the qualitysatisfies relevant regulations, such as ASTM, ISO3696, CLSI, EP, and USP. Theproduced water can be utilized for precision analysis instruments, such asHPLC, AA, ICP, LC-MS, and ICP MS, as well as in the fields of electrochemistry,TOC analysis, molecular biology, and semiconductor engineering. By utilizingmultiple (maximum 3 units) dispensers, final filters can be selected byapplication field to produce water free of particles, endotoxins (pyrogens),and heavy metals. In addition, it is possible to feed necessary quantity of water.The 4.3"-wide graphic display enables real-time identification of quality,TOC value, and PH of ultra-pure water, filter pack utilization condition, andlevel of storage tankAdvanced Multi-Stage Purification

This system employs reverse osmosis, ultraviolet sterilization, and ultrafiltration to eliminate impurities, organics, endotoxins, and particles. Integrated pretreatment and polishing stages enable consistent water quality suitable for the most demanding laboratory and research settings.

Precision Monitoring and Automatic Control

With high-precision dual-range conductivity sensors and microprocessor-based automatic controls, purity is constantly monitored. The digital touchscreen provides instant readout, maintenance alerts, and adjustable parameters for tailored operation and easy user interface.

Safe, Silent, and Reliable Operation

Using noise dampening technology, the system operates at less than 50 dB. The sterile storage tank, vent filter, and continuous recirculation safeguard water from contamination, supporting secure applications in laboratories, pharmaceuticals, and electronics.

FAQ's of Latest Technology Ultrapure Water System:

Q: How does the Ultrapure Water System achieve ASTM Type I water standards?

A: The system uses a combination of multi-stage filtration-reverse osmosis, UV sterilization, and ultrafiltration-to reduce contaminants. Integrated sensors and recirculation continuously monitor purity, ensuring TOC levels below 5 ppb and resistivity up to 18.2 Mcm, meeting ASTM Type I criteria.Q: What dispensing options are available for ultrapure water?

A: The system offers both volume-controlled dispensing for precise measurement and manual dispensing for flexible use, making it suitable for various laboratory and research workflows.Q: When should the filters be replaced in the system?

A: A digital filter lifespan indicator will display a maintenance alert when filters approach the end of their lifecycle, allowing timely replacement for continued water purity with minimal manual oversight.Q: Where can this ultrapure water system be installed?

A: It is designed for benchtop mounting within laboratory, research, pharmaceutical, or electronics environments. The system's compact footprint and integrated tank fit in spaces with access to standard 220V AC power.Q: What is the process for adjusting water hardness in the system?

A: Water hardness can be adjusted during the pretreatment stage. The system allows users to set desired hardness levels according to specific application requirements before final purification.Q: How does the recirculation system benefit water purity?

A: Continuous recirculation ensures the water remains free from static contamination and maintains ultra-low TOC and endotoxin levels, improving water quality for sensitive applications.Q: What are the main benefits of using this ultrapure water system?

A: Users benefit from instant, high-quality ultrapure water, automated maintenance alerts, precise purity monitoring, low noise operation, and robust compliance for critical scientific and industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmaceutical Testing Instruments Category

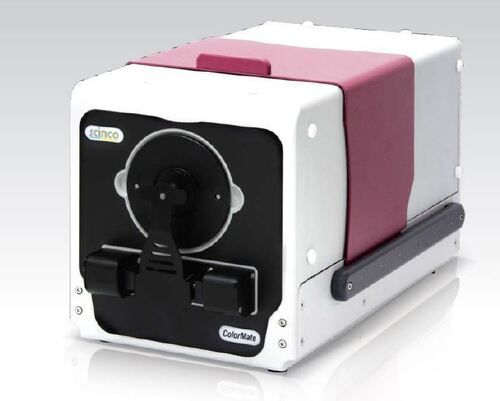

Colour Specrophotometer

Price 900000 INR / Piece

Minimum Order Quantity : 01 Piece

Features : Portable, UserFriendly Menu, Color Matching Functions, Data Storage

Application : Textile, Paint, Plastic, Printing, Food Industry

Mounting Type : Handheld

Usage : Color Measurement & Matching

Texwipe Cleanroom Swabs

Price 4500 INR / Pack

Minimum Order Quantity : 01 Pack

Features : Low particle generation, solventresistant, lintfree, thermally bonded, compatible with most cleaning solutions

Application : Precision cleaning, sampling and contamination control in cleanrooms, electronics, pharmaceuticals, medical devices, and optics

Mounting Type : Handheld

Usage : Surface and equipment cleaning, sample collection, and application of liquids

Laboratory Freeze Dryer Machine

Price 450000 INR / Piece

Minimum Order Quantity : 01 Piece

Features : Corrosion resistant chamber, Overtemperature protection, Transparent drying chamber, Easy maintenance, Oilfree vacuum pump

Application : Pharmaceuticals, Biological, Laboratory Research

Mounting Type : Benchtop

Usage : Lyophilization of laboratory samples

Microwave Digestion System -QBlock Wireless

Price 990000 INR / Piece

Minimum Order Quantity : 01 Piece

Features : Wireless operation, Digital display, Programmable heating, Overtemperature protection, Uniform heating

Application : Laboratory Sample Digestion (Environmental, Food, Pharma, Clinical, Soil)

Mounting Type : Benchtop

Usage : Laboratory Sample Preparation

Send Inquiry

Send Inquiry