Pharma Grade Washers

Price 1500000 INR/ Piece

Pharma Grade Washers Specification

- Application

- Pharmaceutical, cleanroom, hospital equipment assembly

- Mounting Type

- Standard fitted, custom options available

- Max Height

- 2 mm (standard), custom sizes available

- Humidity

- Recommended 60% during storage

- Accuracy

- Dimensional tolerance 0.05mm

- Temperature

- Withstands 150C (autoclave safe)

- Equipment Type

- Pharma Grade Washer

- Features

- High chemical resistance, easy to autoclave, non-reactive

- Power Supply

- Not required for washer itself; automated cleaning equipment: 220V AC, 50Hz

- Specimen Size

- Customized as per requirement

- Port Size

- Available in M6, M8, and custom sizes

- Hardness

- Shore A 60-80 (for silicone washers); Stainless Steel: as per AISI grade

- Automation Grade

- Manual / Semi-automatic compatible

- Usage

- Sealing, separating, load distribution in sterile equipment

- Capacity

- Suitable for bulk and single piece cleaning

- Machine Weight

- Approx 0.8 - 2.0 g (per washer, depending on size)

- Control Mode

- Manual / Automatic cleaning options available

- Thickness Range

- 0.5 mm 2 mm

- Shelf Life

- 5 years from date of manufacture if unopened

- Packaging

- Double or triple sterile polybag, cleanroom packed

- Edge Type

- Chamfered or square

- Minimum Order Quantity

- 50 pieces per size

- Sterilization Compatibility

- Autoclave, ETO, gamma irradiation

- Surface Finish

- Smooth, burr-free, particle-free

- Color

- White, transparent, natural (silicone); metallic (SS)

- Operating pH Range

- 1-13 (for silicone, EPDM)

- Compliance

- FDA, USP Class VI, ISO 10993 for biocompatibility

- Outer Diameter Range

- 6 mm 50 mm (customizable)

- Static Load Capability

- Upto 1000N (for SS washers)

- Density

- Silicone: 1.2 g/cm, EPDM: 1.5 g/cm, SS: 8.0 g/cm

- Odor

- Odorless

- Inner Diameter Range

- 3 mm 30 mm (customizable)

- Toxicity

- Non-toxic, non-cytotoxic

- Reusability

- Reusable after validated cleaning and sterilization

- Material

- Silicone, EPDM, or stainless steel (AISI 304/316/316L)

About Pharma Grade Washers

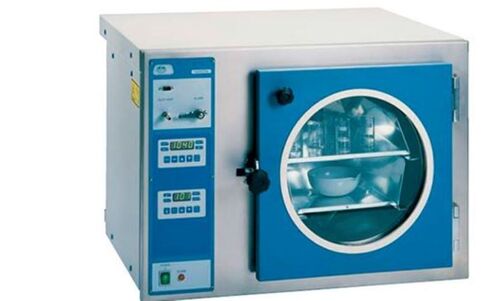

Pharma grade washers are specialised industrial washers made to adhere to the exacting standards of the pharmaceutical sector. Equipment, containers, and other items that come into contact with pharmaceutical drugs are cleaned and sanitised using these tools. These are made with components that guarantee complete cleaning and sanitization. They employ many washing steps to achieve thorough cleaning and remove impurities using high-pressure water and specialised detergents. To further improve their cleaning performance, pharma grade washers also come equipped with features like filtering systems and drying stages. These are made using materials and finishes that are resistant to corrosion, microbiological development, and other elements.

Precision & Sterility for Critical Applications

These pharma grade washers are meticulously crafted to meet the rigorous demands of pharmaceutical and cleanroom settings. They combine precise dimensional control (0.05mm tolerance) with high chemical resistance and non-reactive surfaces. The washers are odorless, non-toxic, and provided particle-free, minimizing the risk of contamination in sensitive equipment assemblies.

Flexible Material & Customization Options

Offered in premium silicone, EPDM, or stainless steel (AISI 304/316/316L), the washers are available in white, transparent, natural, or metallic finishes. Customization extends to outer diameters (6-50mm), inner diameters (3-30mm), thickness (0.5-2mm), and edge types (chamfered or square), ensuring precise fit and performance for your application.

Validated Sterile Packaging & Long Shelf Life

Each washer is double or triple polybagged and packed in a certified cleanroom, supporting even the most stringent sterile requirements. With a shelf life of up to five years if unopened and compatibility with autoclave, ETO, and gamma sterilization methods, these washers are engineered for convenience and long-term reliability.

FAQ's of Pharma Grade Washers:

Q: How are these pharma grade washers sterilized before use?

A: Pharma grade washers arrive double or triple sterile polybagged and cleanroom packed. They are compatible with common sterilization methods including autoclaving at up to 150C, ethylene oxide (ETO), and gamma irradiation, ensuring all washers remain particle- and microbe-free for immediate use in sterile environments.Q: What materials are the washers made from and how do I choose the best one for my application?

A: The washers are manufactured from FDA and USP Class VI compliant silicone, EPDM, or stainless steel (AISI 304/316/316L). Silicone and EPDM offer broad chemical compatibility (pH 1-13), flexibility, and temperature resistance, while stainless steel provides maximum static load capacity (up to 1000N) and durability. Material choice depends on your equipment's chemical exposure, required load distribution, and sterilization processes.Q: When should I replace or reuse pharma grade washers?

A: These washers are designed for reusability following validated cleaning and sterilization procedures. Replace washers if physical wear, degradation, or contamination is observed. Unopened washers have a shelf life of five years from date of manufacture, ensuring long-term storage and readiness.Q: Where can these washers be used, and what are their main benefits?

A: Pharma grade washers are ideal for pharmaceutical manufacturing, cleanroom environments, and hospital equipment assembly. Their main benefits are high chemical resistance, precision fit, easy integration into sterile equipment, non-toxicity, and broad sterilization compatibility, ensuring reliable sealing and separation in critical systems.Q: What customization options are available for size and fit?

A: Washers can be customized for outer diameter (6-50mm), inner diameter (3-30mm), thickness (0.5-2mm), and edge type (chamfered or square). Custom sizes are available on request, allowing seamless integration with various port sizes, machinery, and specific applications.Q: How do these washers support compliance and quality requirements?

A: All washers are manufactured to meet FDA, USP Class VI, and ISO 10993 biocompatibility standards, ensuring safety for direct or indirect medical and pharmaceutical contact. Their particle-free, smooth finish and certified sterile packaging contribute to robust quality assurance in regulated environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Environmental Instruments Category

Analytical Vacuum Ovens

Price 250000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Sample drying and heating under reduced pressure

Interface Type : Analog and digital

Application : Laboratory drying, curing, and moisture extraction

Features : Stainless steel chamber, high vacuum seal, builtin temperature protection

Sample Preparation Sample Clean-up with DEXTech Pure

Price 1500000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Routine and research laboratory cleanup of POPs (persistent organic pollutants)

Interface Type : USB and Ethernet

Application : Automated cleanup of Dioxin and PCB sample extracts

Features : Fully automated fractionation, preprogrammed methods, reproducible results, user safety

QWave Microwave Digestion Systems

Price 990000 INR / Piece

Minimum Order Quantity : 01 Piece

Usage : Laboratory scale digestion

Interface Type : USB, RS232

Application : Sample preparation for elemental analysis (ICP, AAS, MS, etc.)

Features : Programmable methods, safety monitoring, pressure and temperature sensors, data storage

Air Sampler

Price 5000 INR / Pack

Minimum Order Quantity : 01 Pack

Usage : Industrial

Interface Type : Automatic

Application : designed to measure accurate gas range readings in minutes.

Features : Accurate reading in minutes, It is safe and easy to use, No Power is required for measuring, No calibration is Required, Lowcost analysis.

Send Inquiry

Send Inquiry