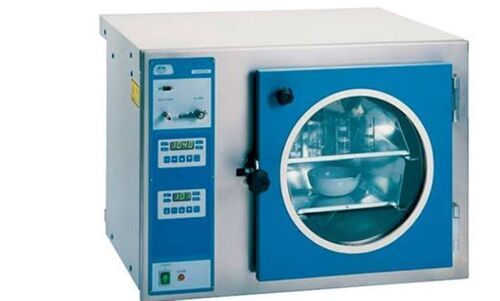

VACUUM OVEN

Price 300000 INR/ Piece

VACUUM OVEN Specification

- Number of Specimens

- Varies on racks; typically 35 trays

- Resolution

- 0.1C

- Equipment Type

- Vacuum Oven

- Application

- Heat treatment, drying, curing, and testing under vacuum

- Interface Type

- Manual and digital controls

- Response Time

- Immediate an indication (depends on system)

- Frequency

- 50 Hz

- Max Height

- Approx. 450 mm

- Operating Voltage

- 220240 V

- Features

- Double-walled, SS304 inner chamber, safety thermostat, glass viewing window

- Measuring Range

- 0250C

- Temperature

- Ambient to 250C

- Power Supply

- 220 V AC, 50 Hz, single phase

- Port Size

- Standard 1/2 vacuum port

- Accuracy

- 1C

- Specimen Size

- Depends on shelf size; e.g., 300 mm x 300 mm

- Gas Pressure

- Up to 760 mm Hg

- Mounting Type

- Benchtop

- Display Type

- Digital LED Display

- Automation Grade

- Semi-automatic

- Usage

- Laboratory, research, and industrial testing

- Capacity

- 50 liters

- Machine Weight

- Approx. 60 kg

- Control Mode

- Digital PID Temperature Controller

- Vacuum Gauge

- Provided, 0760 mm Hg

- Heating Method

- Uniform, indirect heating

- Chamber Dimensions

- Approx. 300 mm x 300 mm x 300 mm (may vary by model)

- Safety Features

- Over-temperature protection

- Chamber Material

- Stainless Steel (Inner), Mild Steel (Outer)

- Vacuum Pump Requirement

- External (not included)

- Insulation

- Glass wool insulation for minimized heat loss

- Temperature Uniformity

- 2C at 100C

- Door Gasket

- Silicone rubber gasket for airtight seal

- Door Type

- Tight sealing with toughened glass window

- Interior Finish

- Polished stainless steel

- Heater Position

- Surrounding chamber

- Shelf Material/Type

- Removable stainless steel trays

About VACUUM OVEN

Vacuum Oven

Digital electronic control of temperature, vacuum pressure and pre selected programmable timer.Temperature sensor Pt100

Automatic air inlet at the end of the operation cycle.

Heating element placed evenly around the chamber.

Chamber made of AISI 304 stainless steel.

Trays made of anodised aluminium.

Door with hardened glass window, which sits on to a silicon gasket that absorbs any contractions and expansions that may occur.

Precision and Efficiency for Laboratory Needs

The vacuum oven delivers dependable and consistent heating for a range of applications, including heat treatment, drying, curing, and material testing under vacuum conditions. Its uniform surrounding heating ensures rapid and even temperature distribution, minimizing sample variability and optimizing processing outcomes.

Flexible and Safe Operation

Engineered with a polished stainless steel chamber and glass wool insulation, the oven minimizes heat loss while providing ample safety through features like a silicone rubber gasket and over-temperature protection. The removable trays and toughened glass window allow for easy customization and safe, real-time observation of specimens.

FAQ's of VACUUM OVEN:

Q: How do I operate the vacuum oven safely during heat treatment or drying processes?

A: To operate safely, ensure the oven is connected to the appropriate 220-240 V power source and an external vacuum pump. Monitor parameters using the digital PID controller and check the vacuum gauge to maintain desired pressure (up to 760 mm Hg). Over-temperature protection and insulated construction help prevent accidents, while the tight-sealing door and silicone gasket maintain an airtight environment.Q: What types of specimens can be placed inside the vacuum oven and how many trays can it hold?

A: The removable stainless steel trays accommodate specimens up to 300 mm x 300 mm each. Typically, 3-5 trays fit within the 50-liter chamber, allowing for flexible arrangement depending on tray size and specimen requirements. This makes it ideal for laboratory, research, and industrial samples.Q: When should I use the vacuum oven compared to conventional ovens?

A: Use the vacuum oven when your process requires controlled heating under reduced pressure, as in sensitive material drying, heat-treating, curing, or vacuum testing. The vacuum environment minimizes oxidation and moisture content, which conventional ovens cannot achieve.Q: Where is this vacuum oven best installed, and what are its mounting requirements?

A: The vacuum oven is designed for benchtop installation in laboratories, research centers, or industrial test areas. Ensure the workspace provides access to power (220-240 V AC), an external vacuum pump, and safe ventilation. The oven weighs approximately 60 kg, so stable, level surfaces are recommended.Q: What benefits does glass wool insulation provide compared to other forms of insulation?

A: Glass wool insulation significantly reduces heat loss, leading to greater temperature uniformity and energy efficiency. Its fire-resistant properties enhance operational safety, while maintaining stable thermal conditions within the chamber even during prolonged use.Q: How does the digital PID temperature controller enhance user experience?

A: The digital PID controller offers precise temperature regulation (1C accuracy, 0.1C resolution) with immediate response on a clear LED display. This allows efficient monitoring and adjustment, ensuring reproducible results and reduced risk of temperature fluctuations during sensitive procedures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Research/ Institutional Instrument Category

Glove Box System

Price 2100000 INR / Piece

Minimum Order Quantity : 01 Piece

Power Supply : 220240 V AC, 50 Hz

Usage : Controlled Atmosphere Handling

Mounting Type : Floor Standing

Application : Laboratory, Pharmaceutical, R&D

Surface Plasma Resonance SPRm 200S

Price 4500000 INR / Piece

Minimum Order Quantity : 01 Piece

Power Supply : AC 100240V, 50/60 Hz

Usage : Laboratory analytical measurement

Mounting Type : Benchtop

Application : Biomolecular interaction analysis, labelfree assay, kinetic study

MANUALCOLONY COUNTER schuett count

Price 250000 INR / Piece

Minimum Order Quantity : 01 Piece

Power Supply : 230 V / 50 Hz or 115 V / 60 Hz (specify with order)

Usage : Microbial colony enumeration

Mounting Type : Benchtop

Application : Colonies counting in microbiological laboratories

Compound Microscope

Price 100000 INR / Piece

Minimum Order Quantity : 01 Piece

Power Supply : Not required (optical device)

Usage : Observation of biological and prepared specimens

Mounting Type : Tabletop

Application : Biological, Laboratory, Educational, Clinical Research

Send Inquiry

Send Inquiry